Role of Laser Alignment Systems in Pump Shaft Alignment

Proper pump shaft alignment is a critical factor in the efficient and reliable operation of industrial pumps. When misalignment occurs, it can lead to a cascade of problems, including reduced pump efficiency, increased maintenance costs, and even premature equipment failure. In this blog, we will explore the role of laser alignment systems in achieving precise pump shaft alignment and the numerous benefits they bring to the table.

The Importance of Precise Alignment

Achieving precise alignment is crucial for several reasons:

- Efficiency: Proper alignment ensures that the pump operates at its highest efficiency, reducing energy consumption and operating costs.

- Extended Equipment Life: Misalignment can lead to premature wear on pump components, reducing their lifespan. Precise alignment extends the life of these components and reduces maintenance expenses.

- Reduced Vibration: Misalignment can cause excessive vibration, which not only damages equipment but also creates a safety hazard for personnel.

- Cost Savings: Accurate alignment reduces the need for frequent repairs and maintenance, resulting in cost savings over the long term.

The Role of Laser Alignment Systems

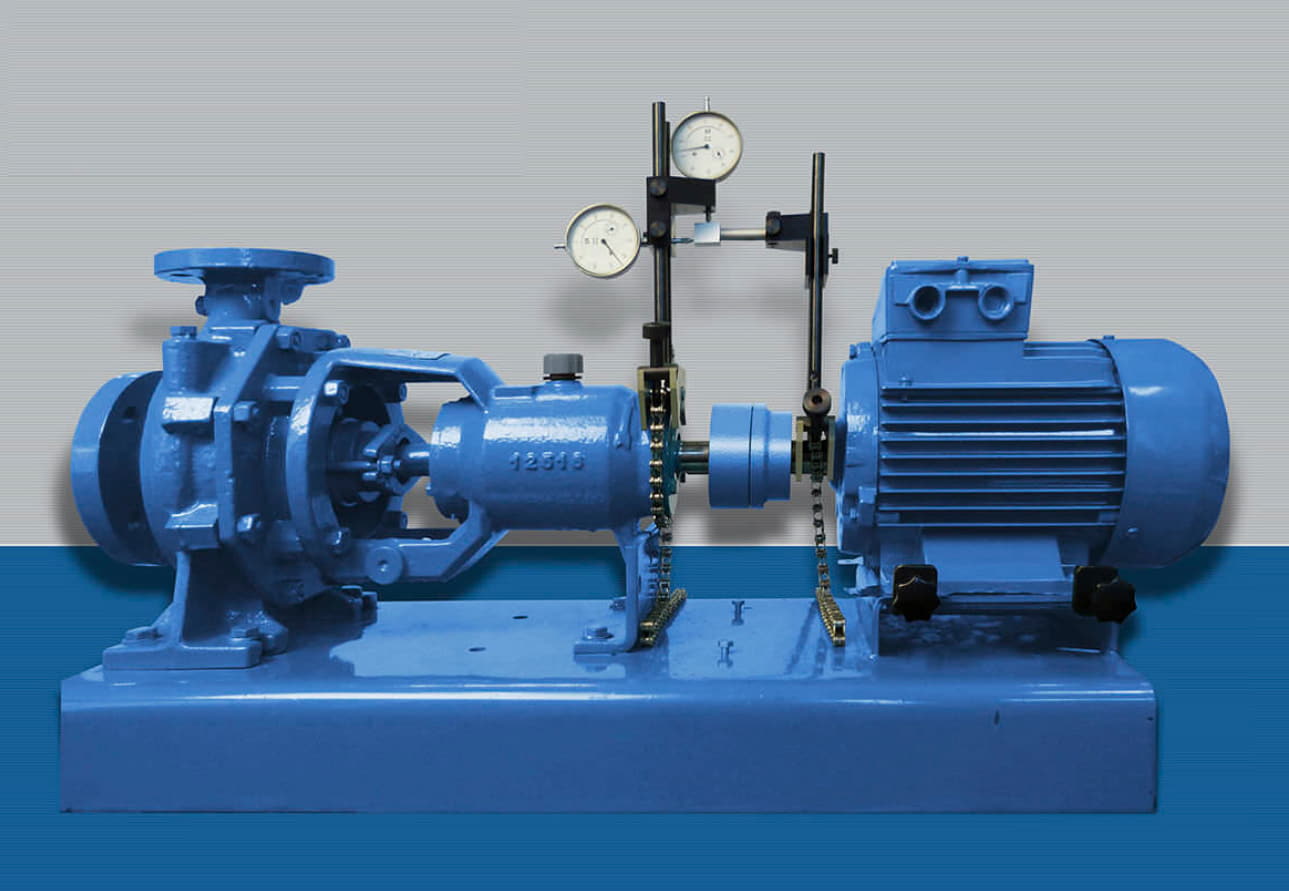

Laser alignment systems have revolutionized the process of achieving precise pump shaft alignment. These systems use laser technology to provide highly accurate measurements and real-time feedback during the alignment process.

Here’s how laser alignment systems work:

- Measurement: Laser alignment systems measure the relative positions of the pump shaft and motor shaft with extreme precision.

- Alignment Guidance: They provide clear guidance on how to adjust the alignment to bring the shafts into perfect alignment.

- Real-Time Feedback: Laser systems offer real-time feedback, allowing technicians to see the effect of their adjustments immediately.

- Data Logging: Many laser alignment systems can log alignment data, providing a record of the alignment process for future reference.

Benefits of Laser Alignment Systems for Pump Shaft Alignment

The advantages of using laser alignment systems for pump shaft alignment are significant:

- Accuracy: Laser systems provide unparalleled accuracy, ensuring precise alignment.

- Time Efficiency: They streamline the alignment process, reducing downtime and saving valuable time.

- Cost-Effective: Laser alignment systems offer a cost-effective solution by reducing maintenance and energy costs.

- Safety: Minimizing vibration through accurate alignment enhances safety in the workplace.

Conclusion

In the world of industrial pumps, achieving precise pump shaft alignment is essential for optimal performance, reduced maintenance costs, and increased equipment lifespan. Laser alignment systems have become indispensable tools in this process, offering accuracy, efficiency, and cost savings.