Use of Metal Laser Cutting

Looking for Metal laser cutting? Even though there are many ways to shape and cut the metal sheet, but a few of them are cost-effective, reliable and precise.

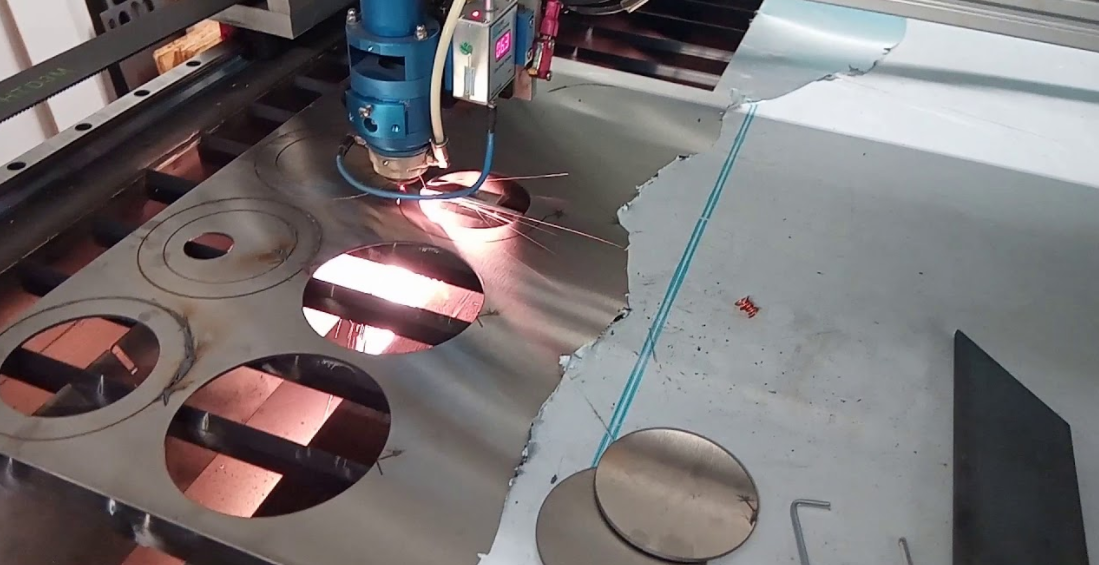

Metal laser cutting technology is one of them that can effectively cut the metal. Its capabilities are in continuation and improving day by day to provide more reliable experience to the user while cutting the metal sheets.

Laser Cutting Tools:

Laser cutting is a reliable and versatile tool that can be used at any type of materials such as glass, wood, stone, sheet metal, and plastic. For metal sheets, sheet metal fabricators are also used for smoothing cutting.

CO2 is also an effective and popular industrial tool for cutting that is affordable as well as highly accurate. It is popular because it is easy to control. In this cutting tool, concentrated CO2 gas is activated by the electricity and used for cutting.

To increase the potential of a seed laser, fibre laser uses the fibreglass in this tool. As a result, you will have a laser that is more precise and powerful as compared to the CO2 laser. The beam of the fibre laser is very focused and intense. That is why it is mostly used to cut metals.

Another laser, Crystal laser, is just like the fibre laser, but it has crystals and pumps diodes that generate the intense and accurate beam of a laser. You can compare the performance of a crystal laser with a fibre laser because of them almost have the same applications.

There are several reasons to use laser cutting when you are developing a metal sheet prototype.

Intricate:

The size of a laser is just of a few centimetres; it can cut the metal sheets with accuracy and precision, which is impossible if you use any other methods for this purpose. That is a thing that you cannot compromise.

Finished Edges:

If you are using any physical methods such as blades to cut the metal sheet prototype, you will have imperfections such as burrs and roughness on the edges of the sheet. In some cases, these imperfections completely buffed out your project or you have to spend more time to complete the product given by the user. But when you use laser for metal laser cutting on your sheet metal prototype, it will not only eliminate the issue but also removes the imperfection from your product.