Strategies for Successful Inverter Testing

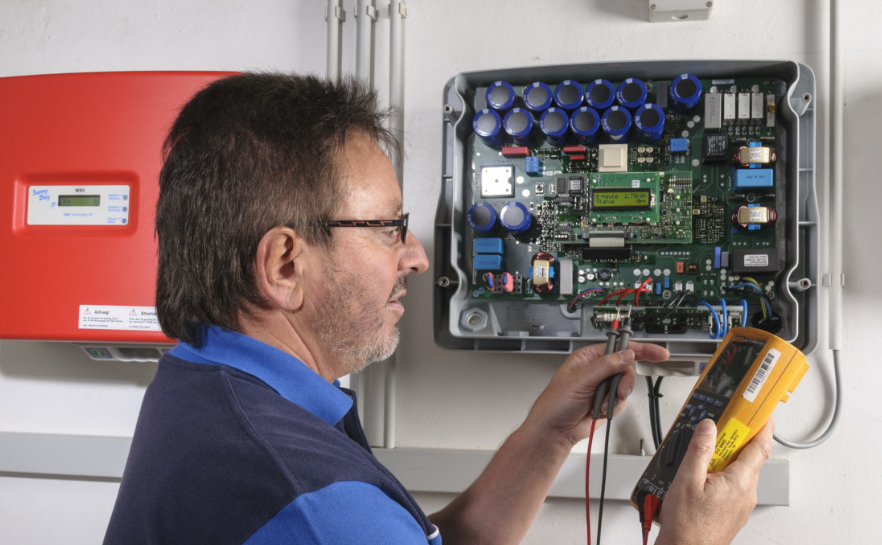

Inverters play a crucial role in converting direct current (DC) into alternating current (AC), which is essential for powering various devices and appliances in both residential and industrial settings. Given their importance, proper inverter testing is essential to ensure they function correctly and safely. This blog post will outline key strategies to achieve successful testing, which can help in maintaining system reliability and efficiency.

Understanding Inverter Specifications

Familiarize with the Inverter’s Features

Before commencing any tests, it is imperative to thoroughly understand the inverter’s specifications. This includes the inverter’s rated output power, input voltage range, output frequency, and efficiency. Knowing these parameters will guide the choice of testing methods and tools, and ensure that tests are conducted within safe and appropriate operation conditions.

Compliance with Standards

Ensure that the inverter meets the relevant national and international standards. Familiarizing yourself with these standards will help in conducting tests that assess whether the inverter can withstand electrical, thermal, and mechanical stresses it may encounter during its service life.

Performance Testing

Load Testing

Conduct load tests to assess the inverter’s ability to handle its rated power output. This involves connecting the inverter to a load that is equal to its maximum capacity and monitoring its performance under these conditions. Observe the inverter’s output waveform and stability to ensure that it meets the desired criteria.

Efficiency Evaluation

Assess the inverter’s efficiency at various loads. Efficiency is critical for energy conservation and operational cost reduction. These tests should be done over a range of different loads to understand the inverter’s performance across its operating spectrum.

Thermal Testing

Overheating can lead to failure and reduce the inverter’s lifespan. Include tests that mimic both normal and extreme operating conditions to gauge the inverter’s thermal management capabilities.

Electrical Safety Tests

Insulation Resistance Testing

Measure insulation resistance to prevent current leakage. Insulation tests are done to ensure that the inverter’s electrical components are adequately insulated, minimizing the risk of shock to users and damage to the inverter.

Grounding Continuity

Test the grounding connections to ensure that they are secure and conductive. This step is vital for safety, as proper grounding protects against electrical faults and potential hazards.

Conclusion

Successful inverter testing is a combination of understanding the inverter’s specifications, thorough inspection, performance evaluations, and diligent maintenance and record-keeping. By adopting these strategies, one can certify the operational integrity and efficiency of inverters, ensuring they are reliable and safe for extended use. Remember, comprehensive testing not only benefits the lifespan of the inverters but also supports the safety and efficiency of the wider electrical system in which they operate.