Understanding the Importance of a Chemical Pump

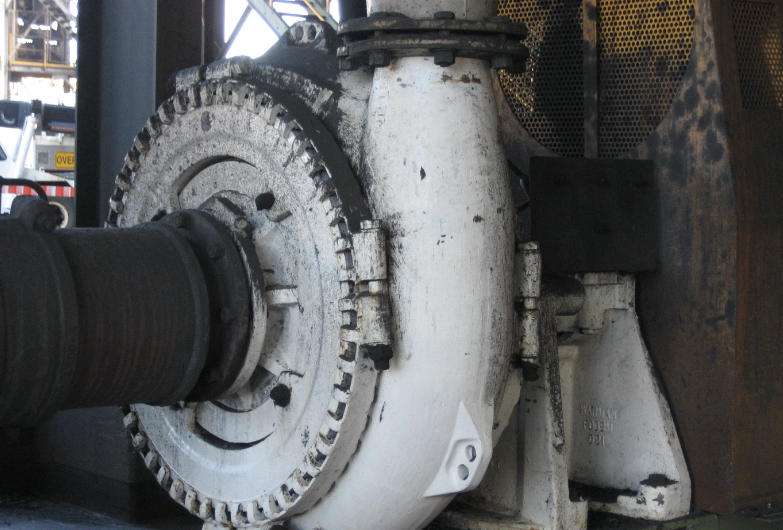

In the world of industrial processes, handling chemicals safely and efficiently is paramount. A chemical pump plays a crucial role in this domain, offering a reliable means to transfer aggressive, corrosive, and hazardous liquids. Whether in the pharmaceutical, petrochemical, or food processing industries, these pumps ensure that chemicals are moved with precision and safety, thereby safeguarding both the environment and human health.

Key Features and Benefits

They are designed to meet the stringent requirements of handling various chemicals. Here are some essential features and benefits:

1. Corrosion Resistance

These pumps are constructed from materials like stainless steel, polypropylene, and Teflon, which can withstand harsh chemical environments. This ensures longevity and reduces the need for frequent replacements or repairs.

2. Versatility

These pumps are versatile in their application. They can handle a wide range of chemicals, from acids and bases to solvents and viscous fluids. This adaptability makes them an indispensable tool across different industries.

3. Safety

Safety is a top priority when dealing with hazardous materials. Chemical pumps are designed with features such as leak-proof seals and robust construction to prevent leaks and spills. This not only protects the workforce but also prevents environmental contamination.

4. Efficiency

Efficiency is another significant advantage. They are engineered to deliver consistent performance, ensuring that the chemical transfer process is smooth and uninterrupted. This efficiency translates to cost savings and improved productivity in industrial operations.

Applications of Chemical Pumps

Chemical pumps are employed in various industries, each requiring precise and safe handling of chemicals. Some notable applications include:

1. Pharmaceuticals

In the pharmaceutical industry, maintaining purity and preventing contamination are crucial. They are used to transfer ingredients and solvents, ensuring that the final product meets stringent quality standards.

2. Petrochemicals

The petrochemical industry deals with highly corrosive and hazardous chemicals. Chemical pumps are essential for transferring crude oil, refined products, and other chemicals used in the production process.

3. Food and Beverage

Even in the food and beverage industry, where hygiene and safety are paramount, chemical pumps are used to handle cleaning agents, additives, and other processing chemicals.

Choosing the Right Chemical Pump

Selecting the right pump involves considering factors such as the type of chemical, the required flow rate, and the operating environment. One reputable brand known for its high quality pumps is Finish Thompson Pumps. These pumps are renowned for their durability, efficiency, and safety features, making them a preferred choice across various industries.

Conclusion

A chemical pump is an indispensable component in the safe and efficient transfer of chemicals across multiple industries. Its design features, including corrosion resistance, versatility, safety, and efficiency, make it a critical tool in industrial operations.