How Beneficial is Precision Maintenance?

Industrial workers should value precision maintenance to leverage all available industrial machines. Most employees might not quickly embrace it, but they later appreciate the essence of it with time.

Here are the benefits of good tool maintenance.

-

Saves money

Proper maintenance of equipment ensures that it remains usable for longer. Therefore, the company will not need to repair or replace it too regularly. In consequence, the company saves a good amount of money over time.

-

Enhances efficiency

Secondly, precision maintenance ensures that a piece of equipment performs optimally. Additionally, this strategy will ensure that experts document accurate measurements for future use.

-

Reduces noise pollution

Misalignment may cause disturbing vibrations making using these tools much more exhausting. Therefore, workers may need to use a pulley laser alignment tool to ensure the pulley is in order. As a result, the machine will produce much fewer vibrations.

-

Enhances productivity

When workers maintain the best precision possible, a machine is less likely to break down. Therefore, laborers can keep working throughout the set working hours. Ultimately, the workers accomplish more, boosting the company’s productivity.

How to Enhance Precision Maintenance

-

Constant re-calibration

Companies should contact calibration experts regularly to fine-tune all equipment, including measurement tools. Machine experts recommend getting these services at least semi-annually.

-

Lubricant

Regular lubrication is essential for all rotating machines, such as pumps, turbines, and compressors. It helps ensure that every measuring equipment is precise and operates for longer.

-

Train the employees regularly.

Companies should invest more money in training workers on different maintenance tasks. Therefore, the employees should take good care of the industry’s rotating equipment. On top of that, they must create a detailed document of how to maintain tools and allow employees to access them freely.

-

Regular tool inspection

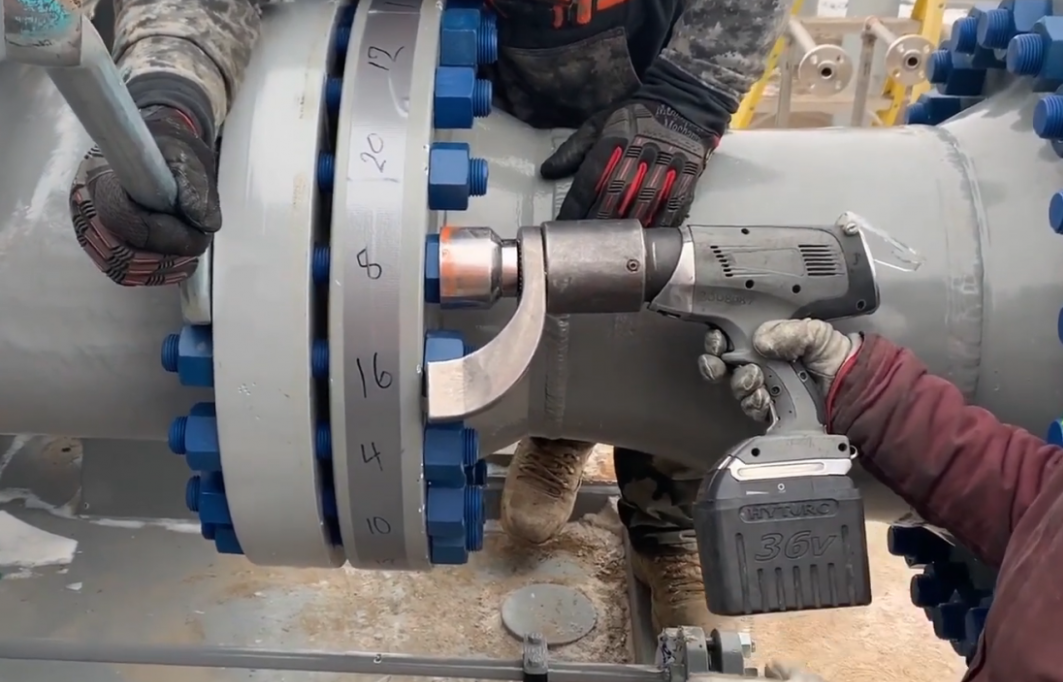

Unquestionably, tool maintenance is expensive but more economical in a way. Thus, businesses should set a sufficient budget to recruit tool experts to inspect their equipment. The professionals may recommend repair services, such as tool re-calibration.

-

Better management of the inventory

Sometimes employees may keep damaging industrial equipment due to recklessness. Therefore, supervisors can enhance accountability by keeping all tool-related information. The worker should ensure they store the equipment properly after use.

Conclusion

Workers need a tool kit to ensure proper precision maintenance of all industrial equipment. The best way to achieve this is to introduce a policy that makes each worker responsible for the tool they use at work.